Vision

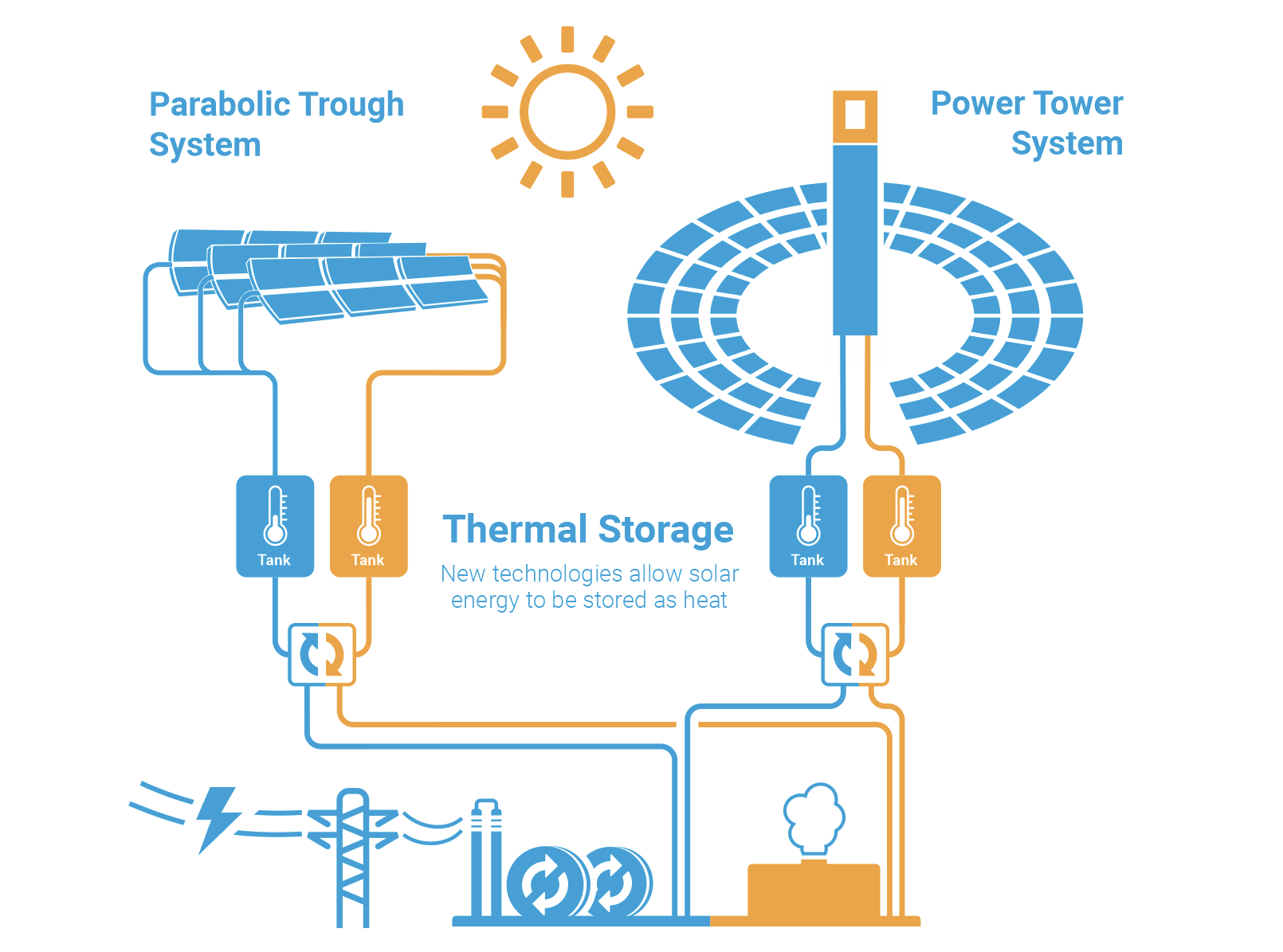

Energy is a core topic to the mitigation of global warming and climate change. Energy storage plays a crucial role in the development, progress and penetration of renewable energy sources, allowing dispatchability of supply. Regarding the current situation of renewable electricity generation, dominated by solar PV and wind, concentrated solar power (CSP) plants is one renewable energy technology with significant potential to increase the share of renewable electricity generation in the future.

This technology has as main feature the possibility of integration, at low cost, of energy storage systems (based on sensible heat), using molten inorganic salts (MS) that are simultaneously used as heat transfer fluids and energy storage media. To meet requirements of high energy density and efficiency, higher temperature fluids are constantly searched.

The use of high temperatures (e.g. up to 700-800°C) in CSP with MS is however quite challenging, taking into account a series of criteria, namely: (a) the allowed temperature working ranges, as wide as possible, which requires low melting points and high decomposition temperatures, ensuring thermal/chemical stability of the salts across the range; (b) the need of ensuring high heat transfer rates; (c) the evaluation of the interaction of materials with the salts, the corrosion effect and the measures to prevent and avoid corrosion.

The present project proposal exactly addressees all these questions, in an integrated and multidisciplinary approach, trying to contribute to the development of reliable and efficient thermal energy storage (TES) systems for high temperatures.

Another activity foreseen, which complements the laboratory investigation, is the energetic and economic impact assessment of the use of new carbonate molten salt mixtures in single tank thermal energy storage systems and in the CSP plant’s solar-to-electricity efficiency, electricity output and levelized cost of electricity.

The results of this project will be a contribution to the development of concentrated solar thermal technologies, with higher operating temperatures, and an incentive to the future application of these technologies.Objectives

NEWS4CSP aims to develop and validate new solutions for thermal energy storage using new formulations of molten salt mixtures with micro/nanoparticles, aiming at attaining simultaneously high working temperatures, high energy density and improved heat transfer rates with low corrosivity for structural materials. At the same time, the project includes an important effort in the development of new coatings for corrosion protection of materials in contact with the heat transfer media and to clarify the influence of cyclic thermal conditions, dynamic conditions and atmosphere in the corrosion behavior of structural materials. Another goal, which involves and complements the other objectives is to understand the impact of these new materials (new molten salt mixtures and coatings) on the energetic and economic performance of a solar tower power plant.

Concentrating Solar Power 101

Work Packages

WP1 – Doping of LiNaK carbonate molten salts (LCMS)

LNEG and FCiências are involved / WP leader is FCiências

Objectives: Doping LCMS with powders and nanoparticles to increase the thermal stability and thermophysical properties

Expected results: Definition of melting temperature and upper limit of temperature as a function of doped materials and achievement of new stable molten salt mixture with enhanced thermophysical properties.

WP2 – Thermophysical and chemical properties of new LiNaK carbonate molten salts mixtures

LNEG and FCiências are involved / WP leader is FCiências

Objectives: To characterize by thermophysical and chemical methods all molten salt (MS) mixtures developed and assess the transformations that occurred in materials and their doped MS in long term experiments.

Expected results: Procedures for accurate analysis of the MS mixtures and their molten nanosalts, namely thermophysical and chemical/morphological properties determinations. Evaluation of the reactions occurring, stability and degradation phenomena in new molten salt systems. Correlations of thermophysical properties for heat transfer and storage calculations.

WP3 – Corrosivity of new LiNaK carbonate molten salts

LNEG and FCiências are involved / WP leader is LNEG

Objectives:

- Assess the corrosion rates of structural materials in contact with the LiNaK carbonate molten salts mixture (with and without the doping materials);

- Assess the influence of doping materials in the carbonate molten salts mixture on the corrosion mechanism.

- Provide information regarding the durability of materials for WP6.

Expected results:

- Obtain the corrosion rate and the kinetic curve for two structural materials in contact with LiNaK carbonate molten salts mixtures (with and without doping materials).

Understand the corrosion mechanism and the role of doping materials in this process.

WP4 – New coating approaches for corrosion mitigation

LNEG and TEandM are involved / WP leader is LNEG

Objectives:

- Optimization and application of metallic coatings by high velocity oxy-fuel (HVOF) and Laser Cladding;

- Evaluate the two corrosion mitigation approaches needed to prevent the corrosion process and increase the durability of structural materials with low costs for temperatures higher than 550°C.

Expected results:

Viability of the application of these coatings in different steel components in contact with molten salts for durability increase of materials with low costs.

WP5 – Dynamic conditions, thermal cycles and atmosphere on the corrosion of materials and stability of molten salts

LNEG and FCiências are involved / WP leader is LNEG

Objectives:

- To design of a new laboratory pilot facility;

- To evaluate the influence of dynamic flow conditions, thermal cycles and atmosphere on the corrosion behavior, corrosion rate of a stainless steel AISI 430 and the stability of molten salts.

Expected results:

Understand and clarify the influence of cyclic thermal condition versus isothermal conditions, the dynamic versus static conditions and the atmosphere in the corrosion behaviour and corrosion rate of metallic materials in contact with molten salts mixtures.

WP6 – Energetic and economic impact assessment

LNEG and FCiências are involved / WP leader is LNEG

Objectives:

- To evaluate the impact of the different carbonate molten salt mixtures in the CSP plant solar-to-electricity efficiency, electricity output and levelized cost of electricity.

- To evaluate the impact of the utilization of these salt mixtures in thermocline energy storage systems’ performance.

Expected results:

Understand the impact of the use of new MS mixtures on the energetic and economic performance of a solar tower power plant and on the performance of thermocline thermal energy storage systems.

WP7 – Management and dissemination

All partners are involved / WP leader is LNEG

Objectives: Management of the project and dissemination

NEWS4CSP outreach activities will cover a wide range of channels to maximize their impact on the wider community of users with the following proposed dissemination activities:

- Hosted on the LNEG website, a webpage will be created for the project. A 3-minute video will be produced and will be available via various social networks to reach out to a broader audience and educate them about thermal storage materials, corrosion at high temperature, concentrating solar power technology and solar energy.

- The partners of the project will participate at respected scientific conferences and publish scientific publications in peer-reviewed journals

- Two webinars about the new materials developed (molten salts and coatings) applied to concentrating solar power technology for the whole community.

- Based on information gathered in the project, a set of guidelines considering the stability of molten salts, corrosion rates and durability of materials in static and dynamic conditions, thermal cycles and atmosphere will be prepared.

It was foreseen that the research skills and resources acquired would make possible to prepare/integrate a new project.

Partners

LNEG is a State laboratory within the Ministry of the Environment and Energy Transition that makes R&D oriented to the society and enterprise’s needs. LNEG’s mission is to promote technological innovation, science and technology oriented for economic development, contributing to increase the competitiveness of economic agents in the context of sustainable progress of the Portuguese economy. It is an active partner of the major networks and collaborative platforms in the areas of energy (EERA JP-CSP and ESFRI’s EU-SOLARIS) and geology. LNEG was the 1st institution awarded with the “HR Excellence in Research” Logo from the European Commission. LNEG is certified according to NP 4457:2007 for the System of Research, Development, and Innovation. LNEG develops R&D activities in Energy Production Systems; Energy Efficiency; Energy Analysis; Hazards and Environment and Materials for Energy. LNEG has a network of accredited laboratories according to ISO/IEC 17025: Laboratory for Biofuels and Biomass; Laboratory of Solar Energy and Laboratory of Materials and Coatings. The team of this project is integrated into LNEG’s Research Units of Materials for Energy, Renewable Energies and Energy Efficiency and the Laboratory of Materials and Coatings, and their technical team and laboratorial resources are available and will strengthen this project.

FCiências.ID is a Non-Profit Private Association, created as a joint initiative of FCUL – a Higher Education institution and 6 private companies, to support, potentiate and develop R&D activities of its associates. FCiências.ID is the legal representative of 19 FCUL research centers, covering the all the fields of Sciences. FCUL, as the host institution of these centers, provides the overall scientific framework and logistic support to research activities.

CQE is the largest R&D unit in the area of Chemistry in Lisbon, with research facilities at both IST and FCUL. Ranked as Excellent in all FCT evaluations, it integrates the Institute for Molecular Sciences, a recently created Associated Laboratory. Its multi- and interdisciplinary research is organized around four Thematic Lines: (1) Synthesis, Catalysis and Reactivity; (2) Materials, Soft Matter and NanoChemistry; (3) Sustainable Chemistry for the Environment, Energy, and Manufacturing; (4) Medicinal and Biological Chemistry for Health.

The team involved in the current project belongs to G10 – Molecular Thermophysics and Fluid Technology, is located in building C8 of FCUL Campus, using #1 Laboratory of High Temperature Processes, #2 Laboratory of Calorimetry and Nanosystems and #3 Laboratory of Laser Applications, with viscosity, thermal conductivity, DSC calorimetry and nanofluids preparation facilities.

TEandM is a Portuguese leader company in advanced materials applications and the use of high‐speed Thermal Spraying Technologies, Laser Cladding and coatings in a Vapor State. The company makes use of new technologies in materials and surface engineering like: HVOF (High velocity oxygen fuel), APS (Atmospheric plasma spraying), EAWS (Electric arc wire spraying), LVOF (Low velocity oxygen fuel), Laser Cladding, PVD (physical vapour deposition) and PACVD (plasma assisted). TEandM has an extensive experience in coating industrial components and parts submitted to aggressive corrosion, oxidation and wear environments. The company can develop and apply from the laboratorial to the industrial scale, surface coating solutions for the project. With experience on applying coating systems for the aeronautical industry, namely compressor blades and vanes, combustion chambers, turbine, engine casings, etc. can give a significant contribute for the development and application of coatings for high temperature and corrosion resistance applications. TEandM will allocate to the project their coating facilities, combining in this case HVOF and Laser Cladding techniques. From the beginning of its activity, the company found about 50 coatings units in 21 registered trademarks, of which 4 with international registration. TEandM has a quality system certification in aerospace series EN 9100 and ISO 9001. Besides that, it’s also R&D and Innovation management system certified by NP 4457:2007

News/Events

Content available soon.

Publications

PAPERS

Nunes, V.M.B., Lourenço, M.J.V., Nieto De Castro, C.A., 2024. Correct Use of Oscillating-Cup Viscometers for High-Temperature Absolute Measurements of Newtonian Melts. Int J Thermophys 45, 64. https://doi.org/10.1007/s10765-024-03355-x

CONFERENCES (ORAL COMMUNICATIONS)

Gil, M., Pedrosa, F., Paiva, T., Figueira, I., and Diamantino, T. C. Corrosão dos aços AISI 316L e AISI 430 em contacto com sais fundidos de carbonatos para armazenamento de energia térmica. XXVI Congresso SIBAE 2024, 19-23 maio 2024, Lisboa, Portugal 19-23 Maio 2024

Diamantino T.C., Pedrosa F., Paiva, T., Figueira, I. , Gil, M., Navas, M. , Veca, E. METHODOLOGIES FOR ASSESSING CORROSION UNDER DYNAMIC CONDITIONS WITH MOLTEN SALTS IN CSP/CST APPLICATIONS. XIX Congresso Ibérico e XV Congresso Iberoamericano de Energia Solar (CIES’24). 19-21 Junho 2024, Évora

Pedrosa F., Diamantino T.C., Gil M., Paiva T., Figueira I. INFLUÊNCIA DA METODOLOGIA EXPERIMENTAL DE REMOÇÃO DE ÓXIDOS NA AVALIAÇÃO DA VELOCIDADE DE CORROSÃO DE AÇOS INOXIDÁVEIS EM CONTACTO COM SAIS FUNDIDOS. XIX Congresso Ibérico e XV Congresso Iberoamericano de Energia Solar (CIES’24). 19-21 Junho 2024, Évora

Mafalda Gil, Fátima Pedrosa, Teresa Paiva, Isabel Figueira, Teresa Diamantino, Maria José Lourenço, Carlos Nieto de Castro. Corrosion and Heat Transfer Fluids in Thermal Energy Storage for Concentrating Solar Power. 3rd Materials for Energy Transition, 22-24 Julho, 2024, Universidade de Aveiro

M.J.V. Lourenço, M.S. Gil, R.A.S. Taranta, J.F. Chainho, V.M.B. Nunes, C.A. Nieto de Castro, “Challenges on the determination of the thermophysical properties of molten eutectic Li, Na, and K carbonate mixtures for thermal storage applications”, 22nd Symposium on Thermophysical Properties, June 23-28, Boulder, Colorado, USA.

CONFERENCES (POSTER PRESENTATIONS)

Teresa C. Diamantino, Fátima Pedrosa, Teresa Paiva, Eduardo Silva, Francisco Gonçalves, Renato Monteiro and João P. Cardoso. NEWS4CSP Project – New Coatings Approaches to Protect Metallic Materials from Heat Transfer Fluids. 30th SOLARPACES Conference, Rome, Italy, October 08-11, 2024 (Book of proceedings with this article published to be made available soon).

João Chainho, Ivo Costa, Valentim Nunes, Maria José Lourenço, João Serra and Carlos Nieto de Castro, “Thermophysical Properties of New Molten Nanosalts”, Institute of Molecular Sciences Open Day 2024, Portugal, October 18, 2024.

Contacts

For more information please contact Dr. Teresa Cunha Diamantino (PI) or Dr. Carlos Nogueira (Co-PI).

LNEG — Laboratório Nacional de Energia e Geologia

Estrada do Paço do Lumiar, 22

Edifício E - R/C

1649-038 Lisboa

Portugal

Phone

(+351) 21 092 46 00

Email

teresa.diamantino@lneg.pt

carlos.nogueira@lneg.pt

© 2024 | NEWS4CSP | Accessibility